Earlier this week, Astute Electronic’s owner and MD, Geoff Hill, discussed counterfeiting practices in Electronics counterfeiting: risks and remedies for Electronics Design. Why is this issue so important at the moment?

There is a likelihood of increased counterfeiting as a knock-on effect of the chip shortage, says Geoff.

“The counterfeiters now, in fact, have original manufacturers’ equipment. They can silkscreen and really make the parts look to be very, very much the part that you require and in some respects, can actually go past first initial tests, electrical tests, or they could actually meet some of the characteristics that would indicate that it’s the same family.

“So it’s quite complex, and over the years, of course, the counterfeiters have become incredibly clever at what they do. They’ve invested fortunes because they’re making so much, so it’s not as basic as it used to be 10, 15 years ago. It’s a really clever business.”

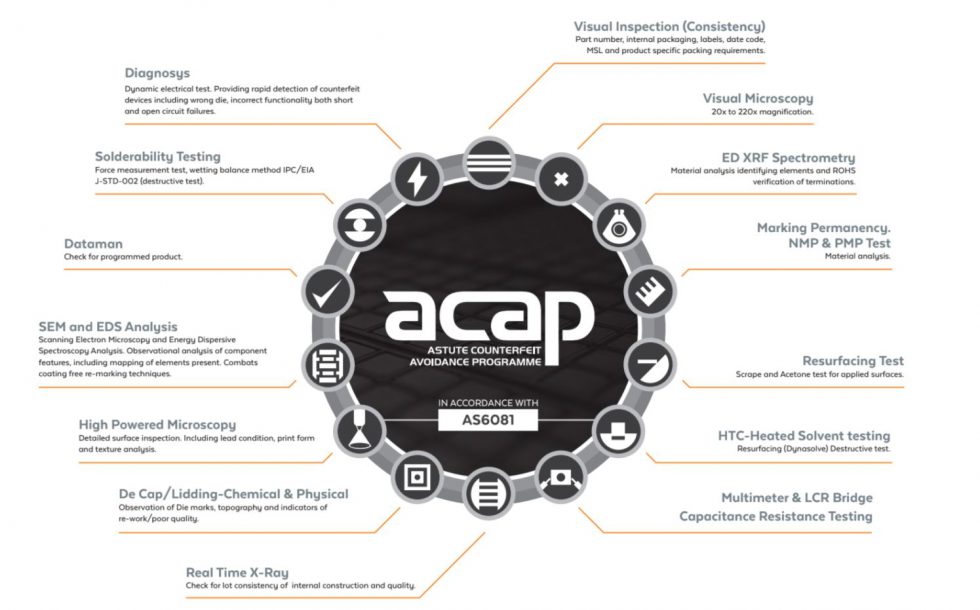

“When you’re buying products without any warranty or traceability, you have to test. There’s a AS6081 spec that we use mainly for semiconductors and for components generally. It ranges a whole range of equipment that we’ve been doing for many, many years.

“Our process starts off with visual microscopy, at 20x magnification (see figure above). Then it goes into spectrometry and material analysis for material elements that might be different. So the amount of gold in there, amount of silver, that sort of thing, which could throw up an anomaly. We also do heated solvent testing using Dynasolve, and the disruptive test on that marking, that highlights any ghost markings.”

“Then you’ve got real-time X-ray. Obviously, you’re looking for the consistency of bond wire that surrounds the die, and making sure that’s 100% consistent within the batch. Then you do a decapsulation, and then topography. Then going back to verify that that die or whatever, its second source is absolutely as per the manufacturer. You do that with high-powered microscopy.”

“Scanning electron microscopy and energy disbursement goes back and uncovers the original coatings, coating upon coating upon coating. Then after that, you do the solderability; you might have an issue with water ingress. It might affect the solderability. You check whether the parts are programmed. Then we also do electrical tests using diagnosis. So we’re actually putting some parametric and functionality tests through electrical capability. All of that, these are fairly advanced, and expensive, and long-winded ways of basically re-verifying your device.”

“The only way to overcome it is to have robust testing and good education, and the communications of what the market is and how we overcome it, and to look for those signs. That’s the only way you can stop it.”

For more help with looking at supply chain options, contact Astute Electronics here