In 2022, the number of reported counterfeit and nonconforming electronic components reported to the supply chain monitoring group, ERAI, increased by 35% from the previous year, writes Evertiq This is despite worldwide semiconductor sales remaining relatively flat.

The increase in counterfeit components is likely due to a number of factors, including the reopening of global supply chains and the return to pre-Covid operations for many enterprises.

“The most interesting statistic from ERAI’s 2022 annual report is that the majority of the parts reported in 2022 – a whopping 80,5% actually – were new occurrences and had not previously been reported,” writes Evertiq. “Analog ICs, programmable logic ICs and microprocessor ICs are still the most targeted component types – accounting for more than half of the reported component types during the year.”

The dangers posed by counterfeit electronic components are much more severe than merely financial damage. If such components end up inside medical equipment, safety technology, or even worse, in aircraft, they can cost lives. For this reason, it is important for companies to take steps to detect and prevent the use of counterfeit components.

There are a number of different methods that can be used to detect counterfeit electronic components. These include:

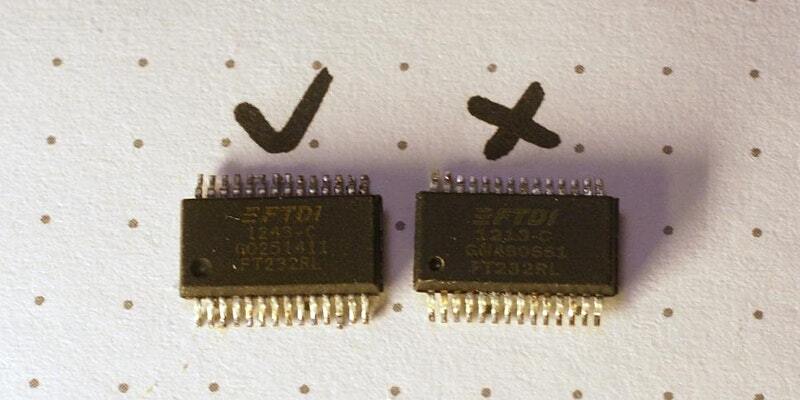

- Optical light microscopy: This method can be used to identify counterfeit components by examining their physical appearance, such as the size, shape, and color of the components.

- X-ray inspection: This method can be used to identify counterfeit components by examining their internal structure.

- X-ray fluorescence (XRF): This method can be used to identify counterfeit components by analyzing the chemical composition of the components.

- Scanning acoustic microscopy (SAM): This method can be used to identify counterfeit components by examining their acoustic properties.

It is important to note that no single method is foolproof. It is recommended that companies use a combination of methods to detect counterfeit electronic components.

In addition to detecting counterfeit components, it is also important to prevent them from entering the supply chain in the first place. Companies can do this by:

- Working with reputable suppliers: Companies should only purchase electronic components from reputable suppliers who have a track record of selling genuine components.

- Requiring suppliers to provide documentation: Companies should require suppliers to provide documentation for all electronic components, such as certificates of authenticity.

- Inspecting components: Companies should inspect all electronic components before they are used in their products.

By taking these steps, companies can help to protect themselves from the dangers of counterfeit electronic components.

To avoid electronics supply-chain disruptions, you may also wish to consult an expert in electronics component supply. With more than three decades of supply-chain expertise, Astute Electronics is ideally placed to work with you on your daily component requirements.

For more help with looking at supply chain options, contact Astute Electronics