Using IoT in supply chain management is a growing trend, reports EPS News, with the power to provide real-time insights into the performance of the entire supply chain and logistics operations.

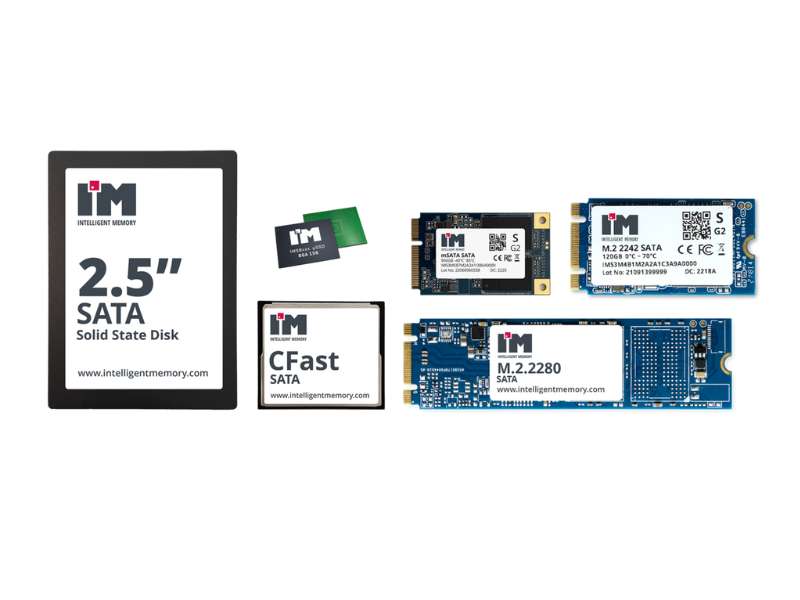

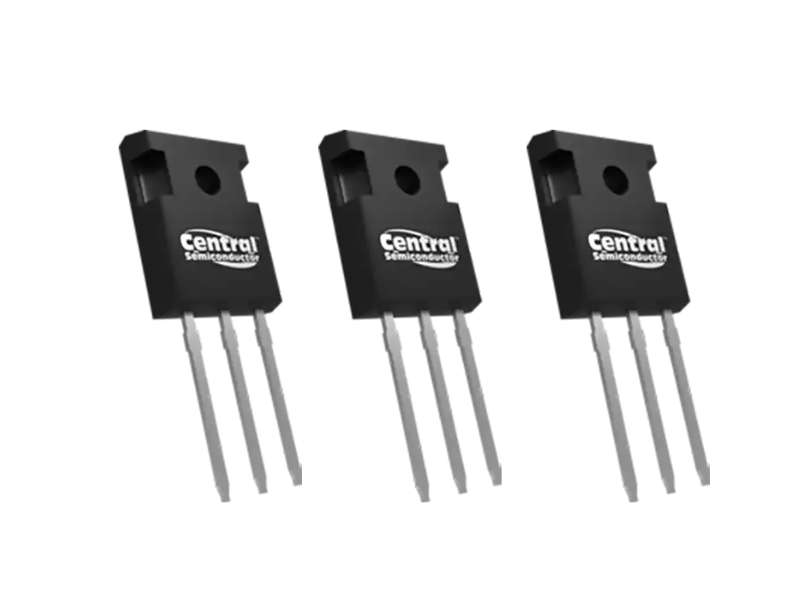

Equipment using advanced IoT sensors can measure various aspects of the surrounding conditions within the supply chain of goods. This includes location, temperature, humidity, light levels, movement, handling, speed of movement, and more. Electronic components are sensitive to humidity, heat and electro-static discharge, for example. IoT devices come in many forms, like RFID chips, smart devices, and mobile sensors.

Key monitoring statistics include:

- Asset tracking: Integrating IoT with the entire trajectory of the supply chain allows a business to monitor the location of goods accurately. You can also track the speed of movement and predict when goods are expected to arrive.

- Inventory management: Smart inventory management using IoT systems facilitates real-time visibility across inventory, warehouse, production, and distribution centers. For instance, sensors installed on shelves transmit real-time inventory information to their management system. This reduces inventory costs by reducing manual labour.

- Monitoring storage conditions: Some raw materials require specific storage conditions. Sudden changes in the temperature, humidity, or exposure to light or the atmosphere can affect the quality of products.

Like to know more about asset tracking? Astute’s SALUS system is a ground-breaking asset tracking solution with a variety of uses. By reporting location, condition and status of assets and equipment, SALUS can dramatically increase productivity, and reduce management costs, resulting in increased operational efficiency. Find out more about Astute’s Salus asset tracking system

For more help with looking at supply chain options, contact Astute Electronics