Supply chain leaders can get ready to adapt and win by thinking differently about digitization, sustainability, and how to reinvent supply chain networks, writes Forbes.

The days of China being a factory to the world may be drawing to an end, as Reshoring accelerates. “China’s problems with COVID, internal unrest, and external adventuring now often outweigh the cost/capability benefits of their spectacular manufacturing base. Production closer to customers saves on transport and inventory which cuts carbon, cost, and risk with shorter supply chains that may finally be a risk adjusted winner for many supply chain strategists,” says Forbes.

Big tech — Apple, Google, Meta, Intel — is slowing down. According to Forbes, “The world has caught up and everyone from regulators (EU, USA), to competitors (TikTok, ChatGPT), to workers (Amazon strikers, Google employee protests) no longer look upon big tech in awe. It is definitely not the end for big tech, but it could be the end of the beginning.”

And finally, automation engineering of supply chains is the hottest ticket, says Forbes. “Reinventing manufacturing by moving to regional supply chains is underway. Everyone from Apple to Zara is rethinking global manufacturing footprints, which means dealing with totally different labor pools, materials suppliers, regulatory frameworks, and customer tastes across geographies. The key to this reinvention adventure will be automation engineers.”

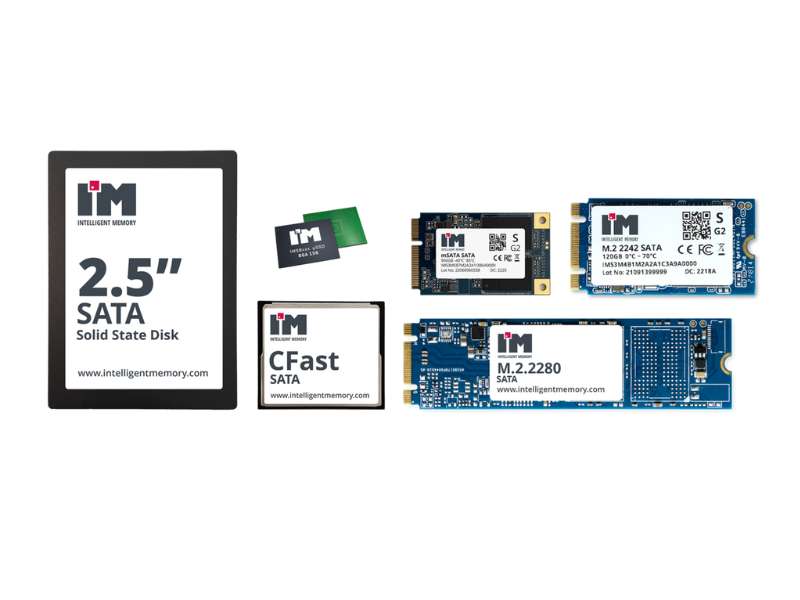

To avoid electronics supply-chain disruptions, you may also wish to consult an expert in electronics component supply. With more than three decades of supply-chain expertise, Astute Electronics is ideally placed to work with you on your daily component requirements.

For more help with looking at supply chain options, contact Astute Electronics