“Most risks to supply chains are predictable,” begins Harvard Review. “That means that companies can and should be prepared to handle them.”

Why prepare? According to HR, companies that are well prepared and as a result prosper in a crisis can expect to recover more quickly than their competitors. “Investors are starting to reward companies that build for the future by becoming more innovative and more resilient.

So, what are the three crucial steps to take?

- Create a world-class sensing and risk-monitoring operation. “If a risk is deemed to be limited, then it can be deprioritized and occasionally reviewed for any increased detectability, but if a risk is deemed high, then a company must actively monitor the situation and take urgent steps to reduce the risk.”

- Simplify your product portfolio. Many products may be low-margin, lack a strategic purpose, require a broader range of suppliers, and lead to higher manufacturing, freight, and out-of-stock costs. Get rid of these.

- De-risk your supply chain. CEOs should, above all, switch manufacturing to locations at home (reshoring), closer to home (near-shoring), or closer to consumer markets (regionalization).

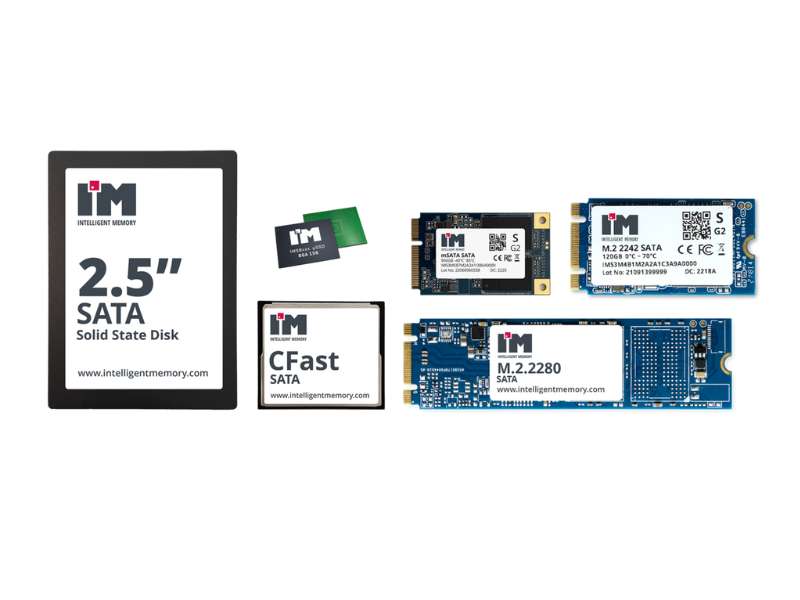

To avoid electronics supply-chain disruptions, you may also wish to consult an expert in electronics component supply. With more than three decades of supply-chain expertise, Astute Electronics is ideally placed to work with you on your daily component requirements.

For more help with looking at supply chain options, contact Astute Electronics