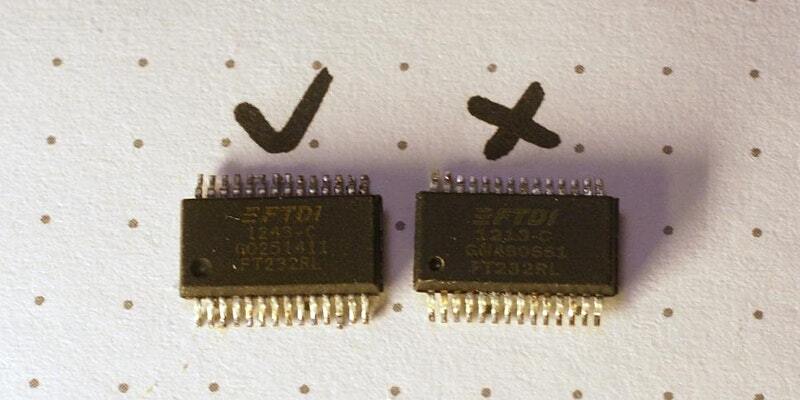

After the groundbreaking U.S. Chips Act and massive government subsidy for electronics manufacturing, will the U.S. see another chips shortage?

According to Fortune Magazine, the unfortunate answer is: Yes, we will.

“Semiconductor demand is unpredictable. The consensus is that future chip demand will be driven by A.I., electric and autonomous vehicles, the Internet of Things, and 5G/6G. Yet the exact nature, speed, and magnitude of that increase in demand is still unknown. This uncertainty makes demand planning hard for chips of different types—logic vs. memory, digital vs. analog, high voltage vs. low power, and so on—and raises the specter of a shortage,” reports Fortune.

They make the point that chip foundries are typically run at close-to-full utilization, which makes chip fabrication notoriously susceptible to unforeseen events – natural disasters, geopolitical surges, sabotage, etc.

Fortune says the amount of investment needed to build a large enough buffer would be prohibitively high, and most countries and companies won’t be able to make the one-time and recurring investments needed to support chip fabrication, especially at the cutting edge.

To avoid electronics supply-chain disruptions, you may also wish to consult an expert in electronics component supply. With more than three decades of supply-chain expertise, Astute Electronics is ideally placed to work with you on your daily component requirements.

For more help with looking at supply chain options, contact Astute Electronics