The real value to having more fabs in the U.S. and Europe is a more diverse—and, therefore, more resilient—semiconductor supply chain, writes Glenn O’Donnell, VP at Forrester Research in Barrons.com

“Just shy of 80% of semiconductor chips are now made in Asia. The Covid-19 pandemic showed the dangers of having too many eggs in that basket. The ongoing chip shortage has many causes, but this overweight geographic focus was certainly prominent among them.

“Semiconductors form the foundation upon which all of this technology is built—all of it, bar none. If the chip supply is at risk, the whole economy is, too.

“Chip making is a long process. Building a chip fab takes even longer. The new fabs planned in places like Arizona, Texas, and Ohio will each take two to three years to build and cost about $20 billion each. Only a few of these proposed facilities have broken ground, and only recently. We won’t see them producing chips until the 2024–2026 time frame.”

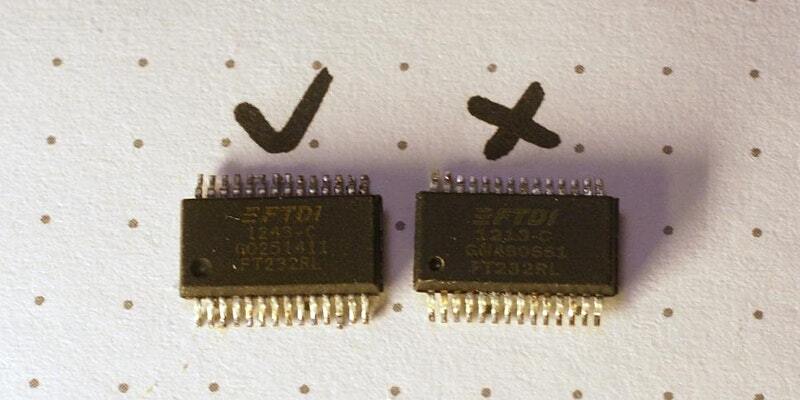

To avoid electronics supply-chain disruptions, you may also wish to consult an expert in electronics component supply. With more than three decades of supply-chain expertise, Astute Electronics is ideally placed to work with you on your daily component requirements.

For more help with looking at supply chain options, contact Astute Electronics