According to EE Times, there are several trends to improve supply networks. Several of them directly impact engineers — and all are worth watching in 2022.

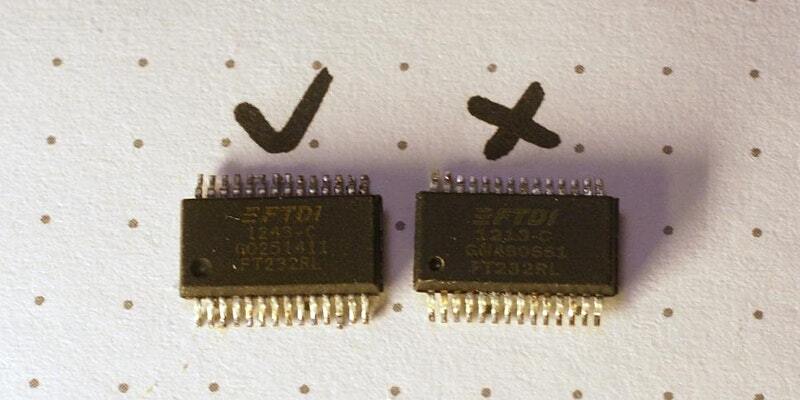

- #1 – Design for Supply Chain (DfSC). This is catching on as component shortages limit industrial production. Automotive companies lost an estimated $210 billion in 2021 due to a lack of chips. DfSC prioritizes components that are readily available, have multiple vendors, are easily swapped, and are even manufactured onshore.

- #2 – Digitisation of Supply Chain. In simple terms, digitising a supply chain means partners are using and sharing data to inform forecasting, inventory, logistics, and a host of other decisions. The goal is end-to-end visibility of a product or service from concept to delivery.

- #3 – Reshoring/nearshoring. Experts say reshoring/nearshoring is vital to building more resilient supply chains that can recover more quickly from disruption. Manufacturers can incorporate and leverage models where components and materials supplies are nearshored and assembly is completed at the point of sale.

- #4 – 3D Printing. All the signs are pointing to the technology stepping up to print parts to support manufacturing and smooth out supply chain gaps even in demanding vertical markets. With distributed manufacturing, manufacturers can produce parts just in time, close to the time of need, and near where it is used.

- #5 – Sustainability. Sustainable supply is the long-term viability of vendors, on-hand inventory, and dependable logistics. Many electronics companies are designing products based more on component availability than on price or performance.

To avoid electronics supply-chain disruptions, you may also wish to consult an expert in electronics component supply. With more than three decades of supply-chain expertise, Astute Electronics is ideally placed to work with you on your daily component requirements.

For more help with looking at supply chain options, contact Astute Electronics